Screen printing – the best technology for textile prints

Screen printing is a traditional and time-tested method for printing on textiles. Coupled with modern technology, it guarantees high-quality and durable prints.

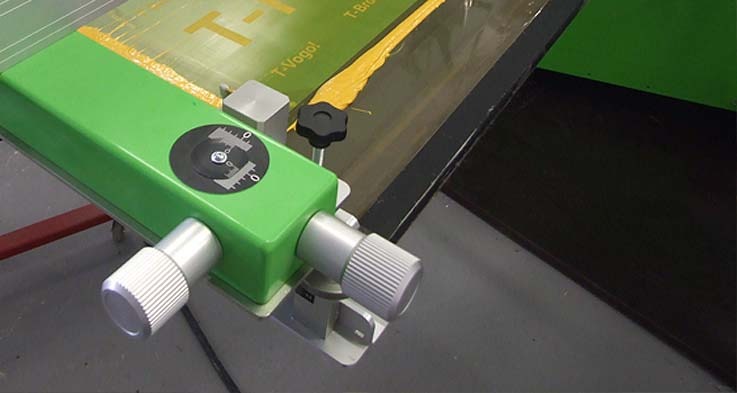

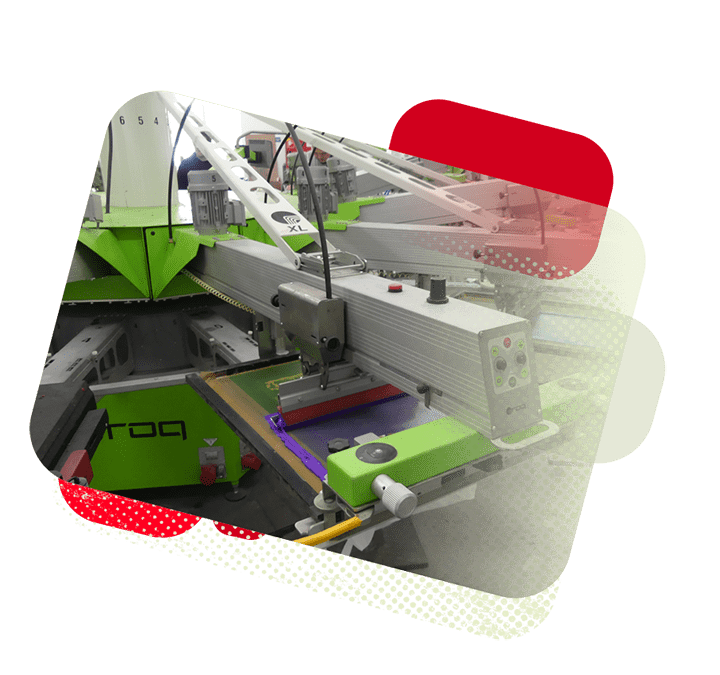

We use a CTS machine from the American manufacturer M&R to create the stencils. The design is applied directly onto the emulsion-coated screen at a rate of 100 stencils per shift, with exceptional edge sharpness and raster detail. This is made possible by a specialised film which prevents light refraction – a common issue with standard films that can cause slight blurring of the raster image. Another huge advantage over a standard film is the precise placement of the print designs onto the stencil. This significantly speeds up the assembly of multi-colour designs on the printer. The new LED exposure unit has significantly reduced the exposure time compared to a standard one. We’ve therefore digitised the print stencil creation process, leading to higher print quality and speed. We print mainly on machines from ROQ, the world’s leading printer manufacturer. The ink is cured in a hot air drying tunnel from the British manufacturer Sanco Technology Limited.

Processing designs for screen printing

Spot colour printing

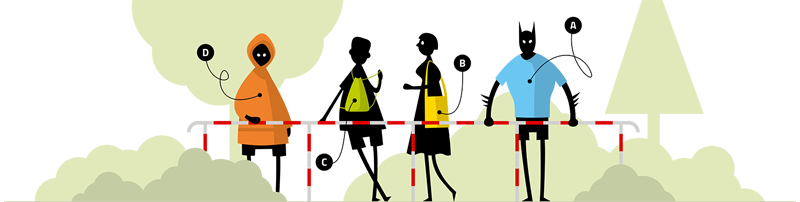

It’s the most commonly used method when screen printing solid, flat areas without raster – it does not allow for colour transitions. The colour scheme is based on the Pantone C colour swatch.

Process colour printing

Two methods can be used for raster images: CMYK process colour printing and Pantone C colour printing. The colours in the Pantone C colour swatch are often used for textile printing thanks to their fullness and boldness – process printing. During separation, the image is divided into four different colours printed as tiny dots that blend together to create the desired colour gradients.

Submit a non-binding inquiry

In the event of any additional questions, we’ll work them out together . Send an inquiry

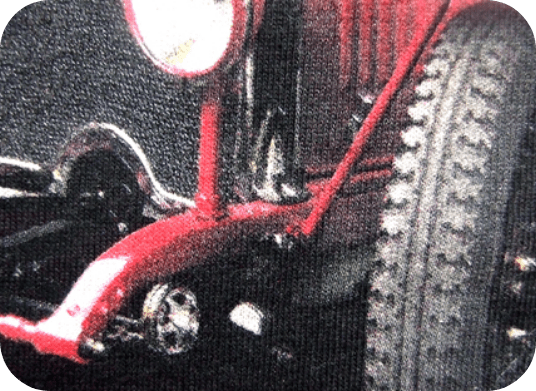

The softest and most breathable screen printing method

The standard method first prints an underlying white ink layer and then applies colour ink. Applying several layers of ink creates a thick, impermeable layer sitting on top of the fabric. That’s why we use the discharge printing method. The dye in the fabric is bleached out and replaced with pigment. The result is a print that is perfectly embedded in the fabric. Colours retain high opacity and saturation and are vibrant but not glossy. The resulting print is soft and breathable.

Screen printing inks

Plastisol inks

Plastisol inks are most often used for printing on textiles as they are vibrant and have excellent covering properties. They meet the requirement for bold, almost rubbery print; however, thanks to our technological processes, we can achieve a soft and breathable print feel.

Water-based inks

Water-based inks are very light and provide a soft feel. They are matt and less vibrant than plastisol inks. They are suitable for printing on highly elastic materials, such as swimwear.