Special effects of screen printing

Unlike other printing techniques, screen printing makes it possible for a variety of special effects to be transferred onto the textile. A suitably selected effect, such as spot varnish, metallic inks or afterglow varnish, can give your design a unique edge. Here are some examples of the most commonly used special effects:

Puff

The puff effect (the additive base that rises up)–a plastic effect with slightly rounded edges, frequently used in printing on textiles, T-shirts and sweatshirts. The template for this type of printing has to be adjusted to this technology. For instance, it is not possible to reproduce thin lines or small font.

Imitation of materials

Suede, leather, or neoprene–these can be imitated by means of printing. The printing can, for instance, imitate denim fabric. Also, the surface of the printing can be cracked. The print imitates the material both visually and to the touch.

3D printing

3D printing on textiles – layered printing; in contrast to the puff effect, it has sharp edges. This printing is very impressive. It also has practical applications; 3D printing is used, for example, for anti-slip elements at the bottom of children’s socks.

Metallic inks, pearl effects

Gold, silver and other metallic inks contain various amounts of very fine metallic particles. By adding pigments to inks, we can achieve different variants and metallic shades. Glitters (pearl effects) create an interesting play on colours from various perspectives.

Glitters

Glitters are very coarse metallic pigments which deliver the printing of specific striking glossy effects. The template for printing must be adapted to these technologies. For example, light lines or small text cannot be reproduced.

Pearl effects

Pearl effects create an interesting play on colours from various perspectives.

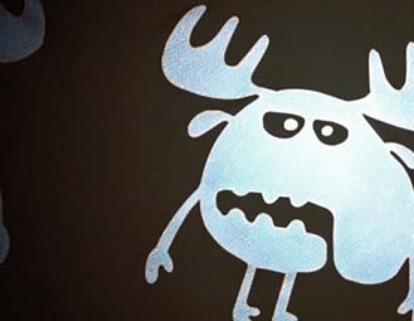

Phosphorescent paint

Special paint with afterglow effect. It stores light from light sources and is then highly visible for a long time, even in the dark. The paint is printed as a translucent layer that can be underprinted in any colour.

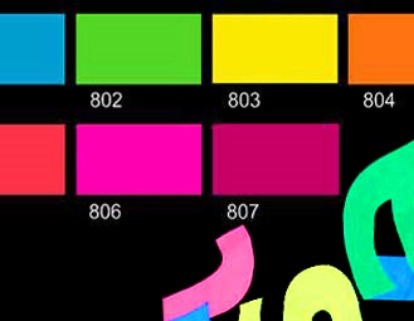

Fluorescent colours

Reflective inks are used for printing on safety clothing and children’s clothing. Fluorescent inks

Reflective colours

Reflective colours are clearly visible when light shines on them. They are used, for example, for printing on safety clothing or children’s clothing, and for accentuating.

Varnishes

Varnish is used for overprint or emphasis of the chosen part or colour. Colourless varnish – “the water effect”; the motif appears to be wet

Transparent

A transparent base is used, for example, to highlight only certain sections of the print on which the transparent base is printed. Can be shiny or matt. Can be sharp or have a very rounded edge (the effect of a drop of water).